|

Sources of Heat Treatment Distortion and Approaches for Distortion Reduction during Quench Hardening Process

|

Download PDF

|

09/30/2024

|

Zhichao (Charlie) Li, B. Lynn Ferguson, Edward Lee, Stefan Habean, and Jason Meyer

|

Distortion, Modeling, Simulation, and Displacement

|

Quenching, Furnace Heating, Stepped Heating, LPC, and Low Pressure Carburization

|

|

|

Modeling the Effect of Chemistry Changes on Phase Transformation Timing, Hardness, and Distortion in Carburized 8620 Gear Steel

|

Download PDF

|

09/14/2021

|

Jason Meyer, Stefan Habean, Dan Londrico, and Justin Sims

|

Heat treatment and Steel metallurgy

|

LPC and Low pressure carburization

|

Quench cracking

|

|

Causes of Distortion during HPGQ Process of Steel Parts (pdf)

|

Download PDF

|

10/19/2019

|

Justin Sims, Zhichao Li, and B. Lynn Ferguson

|

Distortion, High Pressure Gas Quench, and Steel

|

|

|

|

Minimizing Distortion During HPGQ Processes

|

Download PDF

|

01/01/2018

|

Zhichao Li and B. Lynn Ferguson

|

HPGQ and Distortion

|

High Pressure Gas Quench

|

|

|

Solving Critical Heat Treatment Challenges with Practical Process Modeling

|

Download PDF

|

10/24/2017

|

Justin Sims, Tianyu Yu, Charlie Li, and Lynn Ferguson

|

Computer modeling, Heat treatment challenges, Quench cracking, Press quench tooling design, and Carbide formation

|

Induction hardening, Press quench, and Low pressure carburization

|

|

|

Sources of Distortion Study during Quench Hardening using Computer Modeling

|

Download PDF

|

10/24/2017

|

Zhichao Li, Lynn Ferguson, Justin Sims, and Tianyu Yu

|

Distortion, AISI 9310 bevel gear, and Modeling and simulation

|

Quench hardening

|

|

|

Press Quench Process Design for a Bevel Gear using Computer Modeling

|

Download PDF

|

04/18/2016

|

Zhichao Li, Andrew Freborg, and Lynn Ferguson

|

Press quench process design, 9310 Bevel gear, Die tooling, and Distortion control

|

Press quenching

|

|

|

Residual Stress and Bending Fatigue Strength in Carburized and Quench Hardened Pyrowear 53 Steel Gears

|

Download PDF

|

04/18/2016

|

B. Lynn Ferguson, Andrew M. Freborg, and Zhichao Li

|

residual stress, bending fatigue strength, carburized Pyrowear 53 steel gears, bending fatigue test, residual stress measurement, model validation, and loading model

|

vacuum (low-pressure) carburization, subcritical anneal, oil quench, intensive quench, deep freeze, and double temper

|

|

|

Using Heat Treat Simulation to Characterize Sensitivity of Quench Hardening Response in Hot Mill Steel Work Rolls

|

Download PDF

|

04/18/2016

|

Andrew Freborg, Zhichao Li, and Lynn Ferguson

|

Work Roll, Steel Mill Rolling, Sensitivity Analysis, and Quench Hardening

|

Flash Heating and Water Quench

|

|

|

Effect of Steel Hardenability on Stress Formation in an Induction Hardened Axle Shaft

|

Download PDF

|

10/20/2015

|

Lynn Ferguson, Justin Sims, Charlie Li, Valentin Nemkov, Robert Goldstein, and John Jackowski

|

Steel hardenability, Axle shaft, and Alloy chemistry effect

|

Induction hardening, Scanning induction, and Spray quench

|

|

|

Understanding Process Sensitivities in Press Quenching: An Integrated Approach

|

Download PDF

|

10/20/2015

|

Arthur Reardon, Andrew Freborg, Charlie Li, and Lynn Ferguson

|

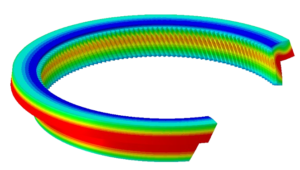

Process sensitivity, Quench cracking, 52100 bearing ring, and Gleason

|

Press quenching

|

|

|

Enhanced Surface Residual Compression of Carburized Steel Parts Using Laser Peening Process with Preload

|

Download PDF

|

06/09/2014

|

Zhichao (Charlie) Li and B. Lynn Ferguson

|

surface residual stress, X-ray diffraction residual stress measurement, carburized AISI 9310 steel, Johnson-Cook, four-point bending fatigue test, residual stress model validation, laser peening model, and fatigue loading model

|

gas carburization, oil quench hardening, and laser peening

|

|

|

Effect of Spray Quenching Rate on Distortion and Residual Stresses during Induction Hardening of a Full-Float Truck Axle

|

Download PDF

|

09/16/2013

|

Zhichao Li, Lynn Ferguson, Valentin Nemkov, Robert Goldstein, John Jackowski, and Greg Fett

|

AISI 1541 Truck axle, Spray quench rate, Distortion, and Residual stress

|

Induction hardening and Spray quenching

|

|

|

Process Innovation to Eliminate Cracking Problems in Large Diameter Parts with Nonuniform Wall Thickness

|

Download PDF

|

09/16/2013

|

Zhichao Li and Lynn Ferguson

|

Process innovation, Cracking problems, AISI 4150, and Large parts

|

Induction hardening and Spray quench

|

|

|

Probe Design to Characterize Heat Transfer during Quenching Process

|

Download PDF

|

09/09/2012

|

B. Lynn Ferguson, Andrew Freborg, and Zhichao Li

|

heat transfer coefficient, heat transfer characterization, process characterization, and equipment characterization

|

water quenching

|

quench probe

|