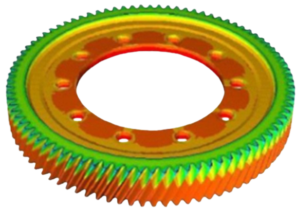

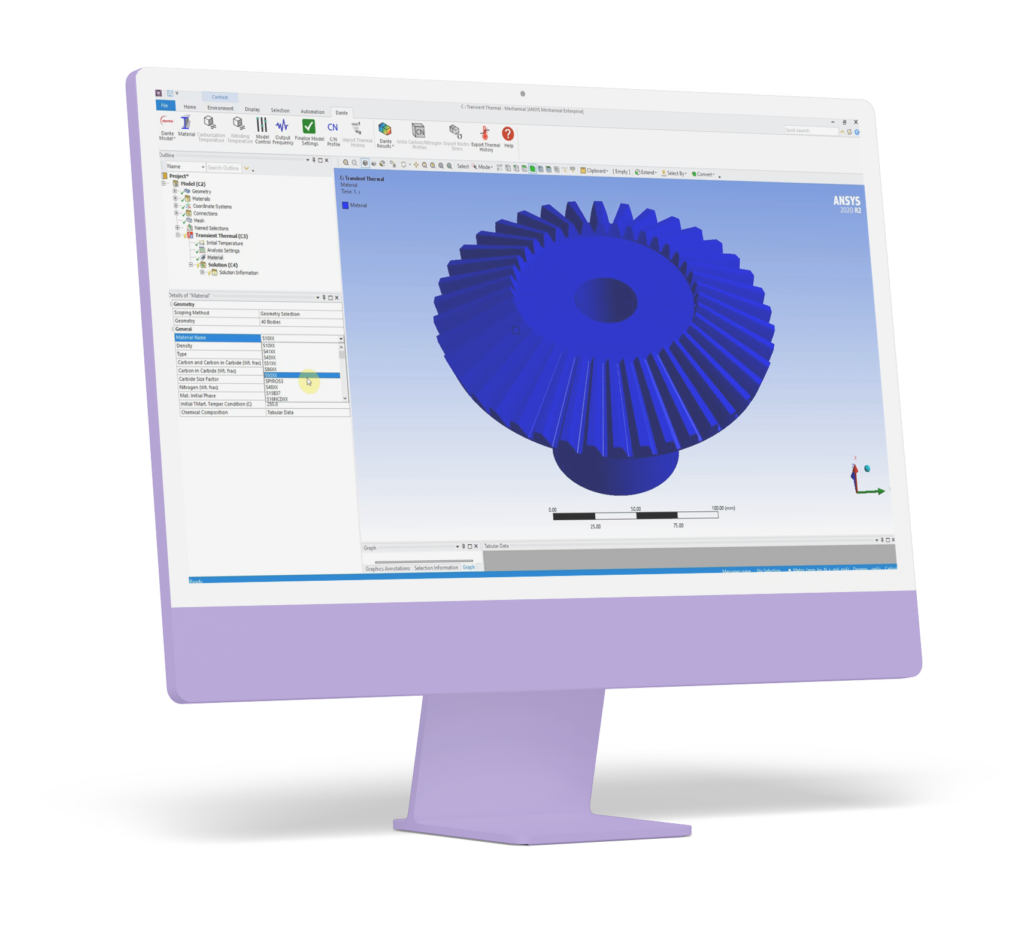

Through DANTE modeling, the blackbox of heat treatment becomes illuminated on a component-specific level by capturing the in-process evolution of microstructural phase transformations, hardness, distortion, and residual stress through our state-of-the-art materials model. This advantage of process modeling helps to provide a deeper insight into the outcomes of heat treat operations.

Those who have heard of Dante know the challenges of heat treatment engineering. Here at Dante, our goal is to help solve those challenges by illuminating the black box that is heat treatment. To solve those problems, we offer a variety of products as well as consulting services.

Dante 6_2a

2/7/2025

- Carburizing model: alloy precipitates (carbides) use actual size (nm) instead of normalized size. The effect of carbide size on carbide decomposition rate is improved.

- Alloy precipitates use actual volume fraction instead of carbon equivalent weight fraction.

- Added a contribution of carbide fraction on individual phase hardness and carbide direct contribution on hardness.

- TRIP parameter update allows for definition of retained austenite below room temperature.

- Effect of carbide volume fraction on carbon diffusivity is updated.

- Implemented martensitic transformation kinetics for diffusive phase effect on further martensitic transformation.

- System variable “DANTE_PATH” is retired. “DANTE_PATH_DIR” is used for future versions.

Dante 6_1

01/2024

- Carbon partitioning for bainite and tempered martensite phases

- Grain growth model implemented

Dante 6_0

06/2023

- Changed material database to keyword format

- Increased user ability to customize, modify, and expand the material database

- Added precipitation hardening model for steel, aluminum, and nickel-based alloys

HTP Sim Utility

06/2023

- Developed a standalone software used to build 1-D heat treatment models

- Includes the ability to model most thermal processes, gas carburizing, low pressure carburizing, and gas nitriding

Dante Utility UI Launch

01/2021

- Launched standalone Dante utility tools with graphical user interface

- Dante utility tools include both material characterization, process design, and prediction

- Material/Process Characterization: Predicton Tools

- TTT_Generator

- CHT_Generator

- Jominy_Predictor

- DI_Predictor

- Material/Process Characterization: Fitting Tools

- Dilot_Fit

- Mec_Fit

- TTT_Fit

- HTC_Fit

- Process Design and Prediction

- VCarb

- Mat_Simulator

- GCarb

- GNitro

Dante 5_1

01/2021

- Rate based austenitizing model

- Added tempered martensite volume change during tempering

Home of The Heat Treatment Simulation Software

Dante Solutions © 2024 All rights reserved