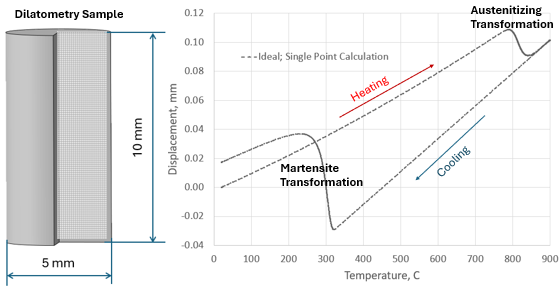

Heat Treatment of steels involves phase transformations: 1) initial phases transform to austenite 2) austenite transforms to diffusive phases or martensite during quenching. A dilatometry test using quenching dilatometer is often using to characterize the phase transformation behavior of steels for computer modeling to understand heat treatment problems such as distortion, quench cracks, and incorrect hardness.

A small sample is used for dilatometry tests to minimize the temperature difference in the sample. The dilatometry curve shown is calculated from the DANTE material database. The curve provides valuable information such as: 1) coefficient of thermal expansion for different phases 2) phase transformation strains 3) austenite and martensite transformation temperature and rates.