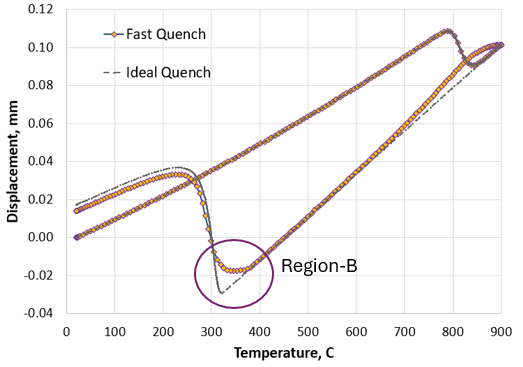

When a dilatometry sample cools to the martensite start temperature (Ms), martensite transformation starts with an expansion. The amount of volume expansion is used to quantify the martensitic transformation kinetics. The temperature uniformity in the sample during martensitic transformation often causes inaccuracies in the collected strain data, as shown in Region B below. The two curves in the graph below are generated using DANTE FEA model, assuming the dilatometry sample is made of AISI 4140 steel. The dash line assumes an ideal cooling without temperature gradient in the sample, while the line with diamond marks has a fast quench rate.

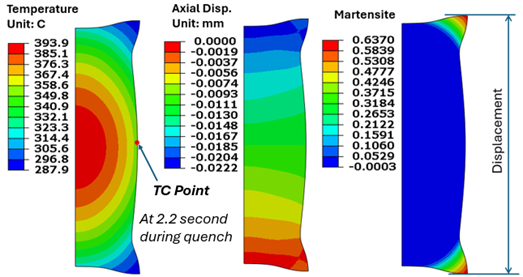

The figure below shows the contours of the simulated temperature, martensite, and displacement at the beginning of martensitic transformation. The dilatometry displacement is measured from the largest distance between the end faces of the cylinder, and the temperature is taken from the middle of the OD surface. Proper selections of the dilatometry sample size and cooling rate are critical for accuracy of the dilatometry data.