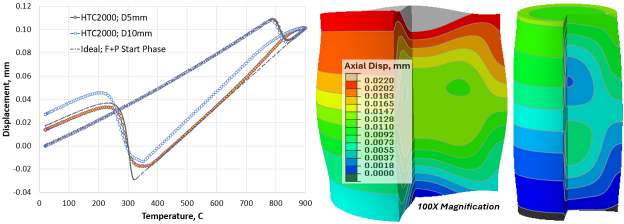

The dilatometry sample size and the quenching rate affect the measured dilatometry curve and the final sample dimension. With a fast quench rate, the simulated dilatometry curve using the 10 mm diameter sample has a larger axial growth as shown in Figure 1. This is mainly caused by the plastic deformation induced by the thermal stress at the beginning of the quenching step. With the 5 mm diameter sample, the thermal stress is below the yield strength of the material, which proves to be true by the matching dilatometry curves between the Ideal and fast quench curves in the temperature range from 400 to 700 °C, as shown in Figure 1. The simulated sample shapes are different between the 5 mm and 10 mm samples. The 10 mm sample shows a more significant OD barrel shape and a crown shape in the end faces.

Figure 1: Effect of sample size on the accuracy of the collected displacement data under high quenching rate