Originally developed as standalone software tools to make quick and efficient assessments of process and material parameters, Dante utilities use the same materials model as the full FEA software, but with simplified modeling assumptions. This allows heat treaters as well as engineers and metallurgists to benefit from heat treatment modeling.

The scope of each utility varies; certain tools are used for process design and analysis, others are used for assessing steel material grade behavior such as phase transformations under processing, while others are useful for fitting material properties and process characterization.

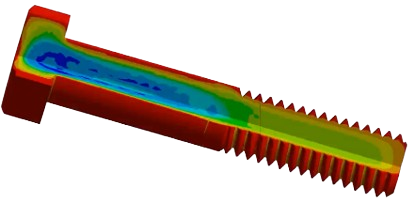

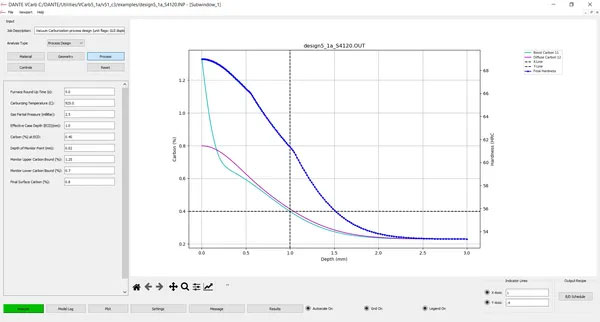

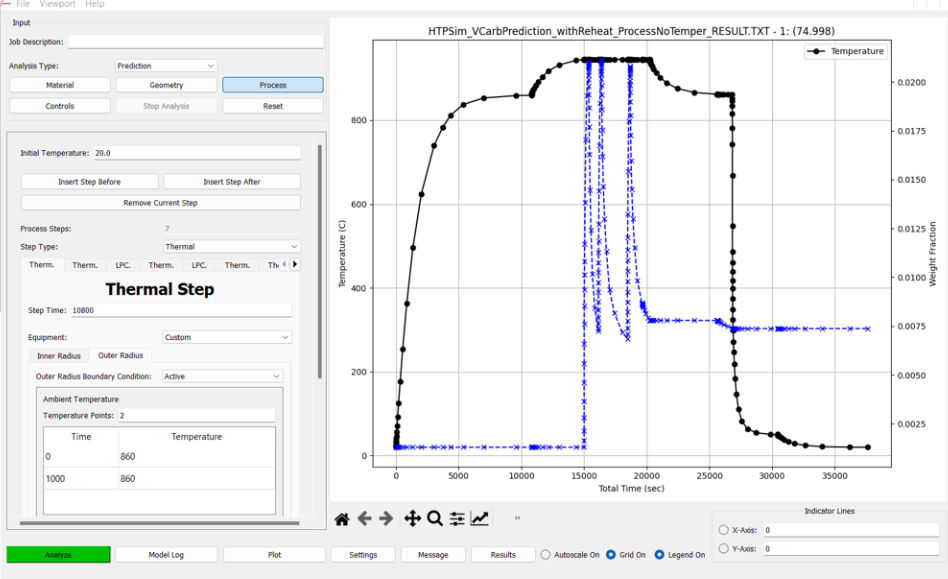

VCarb is used to predict low-pressure carburization (LPC) schedules or to design an LPC schedule for specified input parameters. VCarb uses the DANTE material database and diffusion and carbide morphology models to predict or design these LPC schedules.

VCarb addresses both curved or flat surface geometries. Load surface area is used for gas consumption calculation.

VCarb Controls include unit selections for temperature, time, dimensions, and pressure and flow rate during a pulse step. The carrier gas mixture is defined by the Gas Type Factor and the deposition rate of carbon onto the part surface is defined by the Carburizing Efficiency Factor. The saturation limit of carbon in austenite is defined from DANTE material database, calculated based on alloy composition, or defined by the user.

The VCarb Process definition is used differently depending on the Analysis Type chosen. For Prediction, the LPC schedule in terms of step time, temperature, and the partial pressure of the carbon carrying gas is entered, and the carbon and final hardness profiles are calculated. For Process Design, process parameters such as carburizing temperature, gas type and pressure, aim effective case depth (ECD), carbon level at ECD, and the final surface carbon are used to design the LPC schedule.

GCarb is used to predict carbon and hardness profiles for user specified carburization processes or to design a gas carburization schedule to meet user defined process results. GCarb uses the DANTE material database for these calculations.

GCarb addresses both curved or flat surface geometries. Load surface area is used for gas consumption calculation.

The GCarb Controls include unit selections for temperature, time, and dimensions. The type of gas/gas mixture used is represented by the Gas Type Factor.

For Process Prediction the user enters a gas carburization schedule in terms of step time, temperature, and carbon potential. Multiple process temperatures and/or carbon potentials can be simulated.

For Process Design the user specifies results to be achieved by the carburization process, such as surface carbon level, effective case depth (ECD) and carbon level at ECD. Boost – diffuse processes can be designed, as well as single step carburization processes.

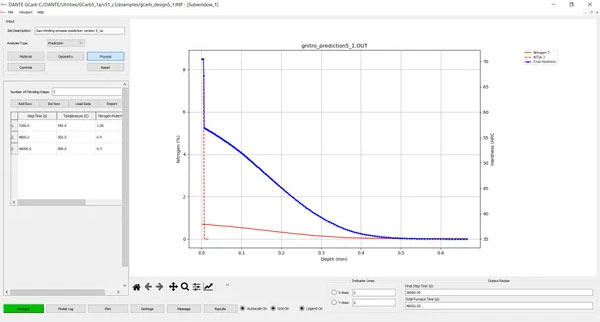

GNitro is used to predict results for specific nitriding processes or to design a nitriding process to achieve user specified results.

GNitro uses the DANTE material database and diffusion and nitride morphology models to predict or design gas nitriding schedules. Base nitrogen, base carbon, and alloy variation from the nominal composition can be considered.

Geometry capabilities of GNitro include both curved and flat surfaces.

The GNitro Controls include unit selections for temperature, time, and dimensions. The type of gas/gas mixture used is represented by the Gas Type Factor.

The GNitro Process definition is used differently depending on the Analysis Type chosen. The Process description for Prediction is used to enter a gas nitriding schedule in terms of step time, temperature, and nitrogen potential. Multiple process temperatures and/or nitrogen potentials can be simulated. The Process description for Design is used to define the furnace roundup time, process targets such as effective case depth (ECD) and nitrogen level at ECD, and the total number of nitriding steps. GNitro predicts the total time needed to reach the specified ECD of the last process step.

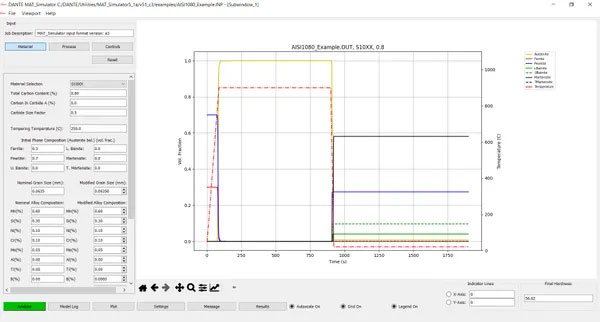

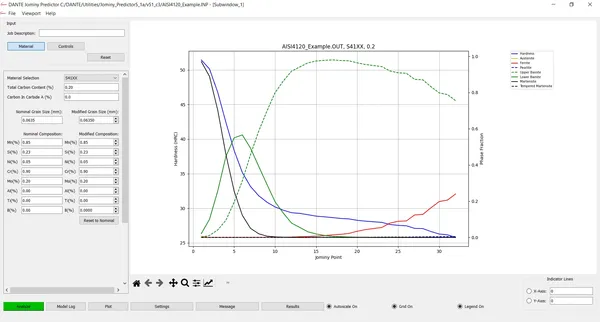

HTPSim can be used to simulate the furnace time needed for heating, as well as hardness and phase transformations from given cooling processes. Many more process can be modeled with HTPSim, like deep freeze, tempering, precipitation hardening, and more.

HTPSim uses the same validated material models of full DANTE FEA package, combining the phase transformation models and the carbon/nitrogen diffusion and carbide/nitride morphology in one complete process model.

HTPSim is easy to use

HTPSim can provide outputs such as hardness, metallurgical phase, and carbon and nitrogen profiles, for a single point over time, or a cross-sectional profile for a single point in the process.

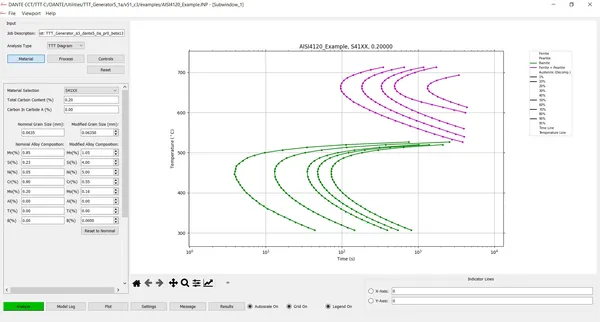

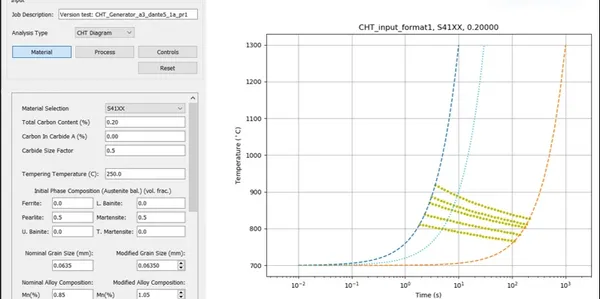

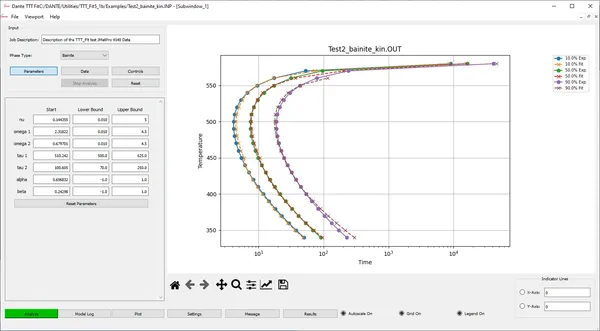

TTTGen uses the DANTE material database transformation kinetics and DANTE material models to generate TTT or CCT diagrams. Carbon in solution, carbon in carbide, and alloy variation from the nominal composition can be considered. TTT and CCT generation use the same Material definition.

TTT Process definition (shown) is defined as the upper and lower temperature bounds and the isothermal holding time. CCT Process definition is defined as starting and ending temperatures and fastest and slowest cooling times.

Both, TTT and CCT, take advantage of the same Controls definition. Controls include activating/deactivating the DANTE Tempering model and the DANTE Carbon Separation model (for carbon rejection during ferrite formation). Control of the maximum changes for phases, temperature, and carbon is also provided. Units can also be changed (℃/℉ and sec./min.).

Home of The Heat Treatment Simulation Software

Dante Solutions © 2024 All rights reserved