|

Distortion Analysis of Landing Gear

|

Download PDF

Download PDF

|

Landing gear, Distortion analysis, Oil quench, 300M, Bow distortion, and Immersion quench

|

|

Heat Treatment Process Development for Gears Using Computer Modeling

|

Download PDF

|

Gear heat treatment process development, Computer modeling, Loading model, Low pressure carburization (lpc), High pressure gas quenching (hpgq), and Thermal/stress modeling

|

|

Strong Bar Competition

|

Download PDF

|

Strong bar competition, HTS, Heat treat process design, Gas carburization, Salt bath, Metallographic analysis, and Hardness measurements

|

|

Axle Shaft Induction Scan Hardening

|

Download PDF

Download PDF

|

Truck axle shaft, Induction scan hardening, Spray quench, Scanning inductor, Quench rate sensitivity, Stress formation, Distortion, and AISI 1541, 1040, 4140

|

|

Understanding Process Sensitivities in Press Quenching

|

Download PDF

|

Press quench process sensitivities, AISI 52100 bearing ring, and Quench cracking

|

|

Using DANTE during Product Design - Correcting Bevel Gear Distortion from Heat Treat

|

Download PDF

|

Bevel gear distortion, Carburization, oil quench hardening, Process change, and Induction heating

|

|

Distortion Minimization of a Press Quenched Bevel Gear - Using DANTE for Troubleshooting and Press Quench Process Design

|

Download PDF

|

Press quenched bevel gear, AISI 9310, Carburization, Press quench tooling, Press quench plug design, Bevel tooth distortion, and Bore distortion

|

|

Immersion Quenching of Long Components - Using DANTE and ANSYS to evaluate the effects of simulating the immersion process for long components

|

Download PDF

|

Immersion quenching, AISI 9310, Bow distortion, and Immersion rate

|

|

Low Pressure Carburization Process Improvement for a Ring Gear Controlling Carbide Formation during LPC

|

Download PDF

|

Low pressure carburization (lpc), Vacuum carburization, Controlling carbide formation, Ferrium C64, LECO burn test, Carbon profile, LPC process redesign, and Primary carbide formation

|

|

Scanning Induction Hardening of Steel Coupler

|

Download PDF

Download PDF

|

Scanning induction hardening, AISI 4340 steel coupler, Crack possibility, Process redesign, Preheating, and Internal stress

|

|

Induction Hardening of Welded Tube Shaft

|

Download PDF

|

Induction hardening, 4130/10B37 welded tube shaft, and In-process stress mechanisms

|

|

Improving Gear Tooth Bending Fatigue Life

|

Download PDF

|

Gear tooth bending fatigue life, Pyrowear 53, Intensive water quenching, Oil quenching, helicopter transmission, and Spur gear

|

|

Quench and Temper of Steel Rolling Mill Roll

|

Download PDF

|

Steel rolling mill roll, Quench hardening, Temper, Surface compressive stresses, and Differential hardening

|

|

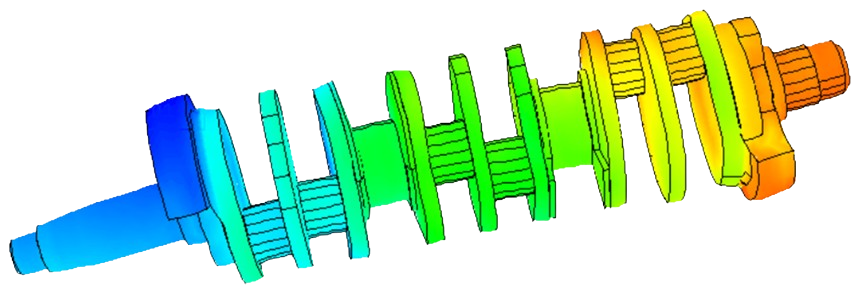

Oil Hole Crack of Crankshaft During Induction Hardening

|

Download PDF

|

Crankshaft oil hole crack and Induction hardening

|

|

Characterizing equipment using simple modeling tools

|

Download PDF

|

Quenching, Heat Transfer, Salt, HTC, HTCFit, Metal Urgency, and Rapid Quenching

|