|

Press Quenching of a Bearing Ring

|

Cracking, Press Quench, Bearing Ring, Martensite, and Maximum Principal

|

Watch Animation Video

|

|

Aluminum Aging

|

Aluminum, Aging, Precipitation, Solution treatment, and Quenching

|

Watch Animation Video

|

|

Rotational Induction and Spray Quench

|

Scanning, Induction, Spray Quench, Axial Stress, and Ring

|

Watch Animation Video

|

|

Carbide Formation and Dissolution during LPC

|

Low Pressure, Carburization, LPC, Carbide, Dissolution, Carbon, Boost, and Diffuse

|

Watch Animation Video

|

|

Non-Uniform Cooling During High-Pressure Gas Quench

|

High Pressure Gas Quench, Non-uniform, Phase transformation, and Boundary conditions

|

Watch Animation Video

|

|

Welding Animation

|

Additive Manufacturing, Welding, Phase Transformation, and Wire Arc Additive Manufacturing

|

Watch Animation Video

|

|

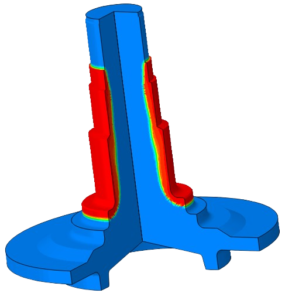

Press Quench of a Bevel Gear

|

Press Quench, Phase Transformation, Expander, Die, and Bevel Gear

|

Watch Animation Video

|

|

Bevel Gear Gas Carb Oil Quench

|

Bevel Gear, Gas Carburization, Austenite, von Mises, Distortion, and Phase Transformation

|

Watch Animation Video

|

|

Residual Stress During Loading

|

Residual Stress, Spur Gear, Loading, and Heat Treatment

|

Watch Animation Video

|

|

Dante Abaqus Heat Treatment Simulation: Gas Carburization Model Tutorial

|

Heat Treatment, Modeling, Simulation, Abaqus, Tutorial, and Gas Carburization

|

Watch Animation Video

|

|

Dante Abaqus Heat Treatment Simulation: Thermal Model Tutorial

|

Heat Treatment, Quenching, Modeling, Simulation, Abaqus, Tutorial, and Thermal

|

Watch Animation Video

|

|

Dante Abaqus Heat Treatment Simulation: Stress and Distortion Model Tutorial

|

Heat Treatment, Stress, Distortion, Modeling, Simulation, Abaqus, and Tutorial

|

Watch Animation Video

|

|

Dante Abaqus Heat Treatment Simulation: Press Quench Tutorial Thermal Model

|

Heat Treatment, Press Quench, Modeling, Simulation, Abaqus, and Tutorial

|

Watch Animation Video

|

|

Dante Abaqus Heat Treatment Simulation: Press Quench Tutorial Stress Model

|

Heat Treatment, Press Quench, Stress, Distortion, Modeling, Simulation, Abaqus, and Tutorial

|

Watch Animation Video

|

|

DANTE Webinar - Quench Cracking

|

Cracking, Webinar, Heat Treatment, and Induction

|

Watch Animation Video

|

|

DANTE Webinar - Heat Treatment Process Design and Optimization using HTP Sim

|

Heat Treatment, HTP Sim, Process Design, Process Optimization, Modeling, Simulation, and Webinar

|

Watch Animation Video

|

|

DANTE HTP Simulator Tutorial: 1-D Heat Treatment Modeling of Quench and Temper

|

Heat Treatment, Modeling, HTP Simulator, and Simulation

|

Watch Animation Video

|

|

VCarb Utility Tutorial: Design and Predict Low Pressure Carburizing Schedules

|

Utility, Tutorial, VCarb, LPC, and Low Pressure Carburizing

|

Watch Animation Video

|