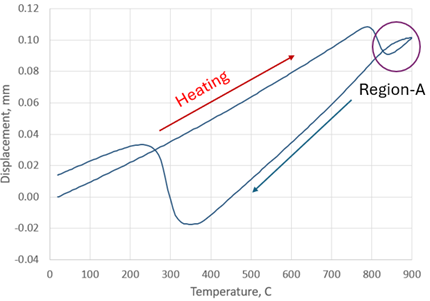

At the beginning of quenching, in a dilatometry test using a dilatometer, temperature uniformity often leads to inaccuracies in the recorded strain data, as seen in Region A in the figure below.

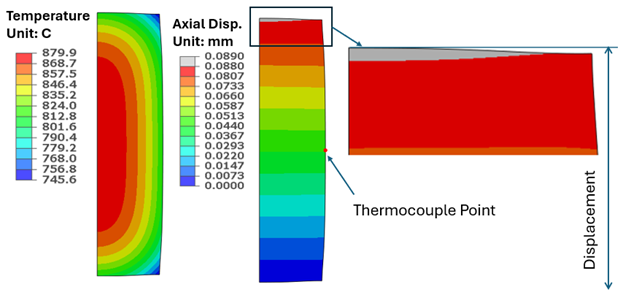

The sample is cooled from both the outer diameter (OD) and the end surfaces. A higher quenching rate increased the data inaccuracy as demonstrated by modeling in the figure below. The dilatometry displacement is measured from the largest distance between the end faces of the cylinder, and the temperature is taken from the middle of the OD surface. Proper selections of the dilatometry sample size and cooling rate are for the accuracy of the dilatometry data.